Brief introduction

MVR processing technology, also known as mechanical steam compression technology, is a new type of energy-saving evaporation technology. Its working process involves low-temperature steam being compressed by a compressor, increasing temperature and pressure, and increasing heat concentration before entering the evaporator for heat exchange and condensation, in order to fully utilize the latent heat energy of steam vaporization. Therefore, in the evaporation process, the high-efficiency evaporator no longer requires a large amount of steam as the main heat source, only steam with less than 10% evaporation capacity is needed as supplementary steam to compensate for inevitable heat exchange losses and system heat dissipation.

Advantage

Low energy consumption and low operating costs;

Small footprint;

Insufficient supporting facilities for public works and low total investment in the project;

Smooth operation and high degree of automation;

Due to the commonly used single effect, the product has a short residence time;

The process is simple and practical.

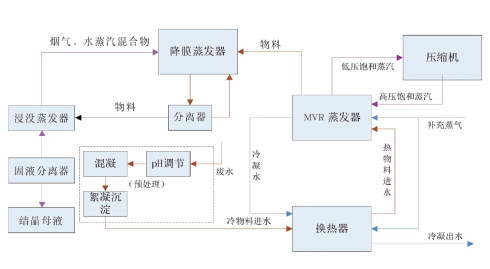

Process flow diagram